Right Social Links

- Ultra High-precision Distance Measurement

- Precise Angle Accuracies 0.5″(NET05AXII)/1″(NET1AXII)

- 1″ Auto Pointing Accuracy*

- Remote Control through on-line PC

- Exclusive Reflector Prescan Technology

- Enforced Durability for Long Term Deformation/Monitoring Applications

For Monitoring

Engineering structures, such as buildings, dams, tunnels and bridges, can always be affected by movement caused by excavation, heavy construction and piling placement, in addition to natural hazards, such as harsh weather, soil movement, change of ground water level or any number of other factors. The ultimate goal in any project, at any job site, is to secure the safety of people and equipment, and therefore the saving of maintenance cost.

The NET series provides superior measuring precision and is equipped with environmental protection and various functions necessary in monitoring applications and therefore, can be utilized to configure a high-precision monitoring system.

For Industrial Measurement

NET05AXII, used with reflective sheet targets, can achieve sub-millimeter accuracy.

It is suitable, therefore, for measuring the shape and alignment of large scale structures, such as various plants and bridges, as well as for precise measurement of ships, railroad cars and airplanes.

For 1st Order Survey

The NET series offers high-precision angle accuracy (NET05AXII: 0.5″, NET1AXII:1″) which can be applied for a wide range of precise measurements.

Since it is equipped with an automatic tracking system, the high-precision 3D station can be configured with a remote control system.

Ultra High-precision Distance Measurement

NET05AXII

Using reflective sheet targets, the NET05AXII provides sub-millimeter accuracy (0.5mm + 1ppm) in a range of up to 200m.

NET1AXII

The reflectorless measurement range of the NET1AXII model is doubled to 400m (1,310ft.) with Kodak white side (90% reflective).

Advanced Angle Measurement System

SOKKIA’s IACS (Independent Angle Calibration System) technology provides “best in class” angle accuracy, 0.5″ (NET05AXII) / 1″ (NET1AXII).

Adjusting mechanism for angle measuring

The biaxial level compensation mechanism has a wider adjusting range of ±6′ which is twice as wide, compared with previous models. This enables highly accurate measuring performance.

Superior Auto-Pointing Accuracy

The auto-pointing accuracy* with the standard prism is 1″ (1mm@200m), and 4″ (1mm@50m) with a reflective sheet.

* Auto-pointing accuracy is verified using the methods specified by ISO 17123-3.

Target Illumination

Prisms or sheet target can be located easily in dim lighting conditions using the high-intensity white LED built into the telescope.

Dust and Water Protection IP65

Provides protection from dust and driving rain as well as other inclement weather conditions. Operates in temperatures from -20 to +50ºC.

Upgraded durability

Improved durability by changing and redesigning the assembling parts,

especially for “24-7 monitoring operation”.

Remote operation by online system

A library of special control commands can be provided in order to establish remote operation functionality in your own monitoring system. *Please contact us for the details of the special commands.

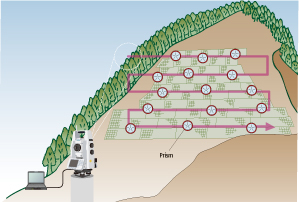

Reflector Prescan function* for Monitoring Setup

This function is ideal for structural monitoring applications to make initial setup easy and fast.

The NET series automatically searches within the predetermined area to quickly measure the reflectors as initial positions for subsequent routine measurements.

This function works even in low light or dark conditions where the reflectors cannot be clearly seen by the human eye and provides greatly increased efficiency in initial reflector search.*This function is not included in on-board software, and need to be implemented in the user’s own system using opened command.

Advanced Auto-Pointing Algorithm* for multiple prisms

The NET series incorporates an advanced auto-pointing algorithm* optimized for monitoring applications. The NET series automatically sights the prism closest to the telescope center regardless of the distance from the instrument. This works even if multiple prisms or other reflective objects are in the field of view.

This feature dramatically enhances the reliability in periodic monitoring of predetermined prism locations.

* With a regular auto-pointing algorithm, the instrument normally sights the nearest target with the strongest reflection.